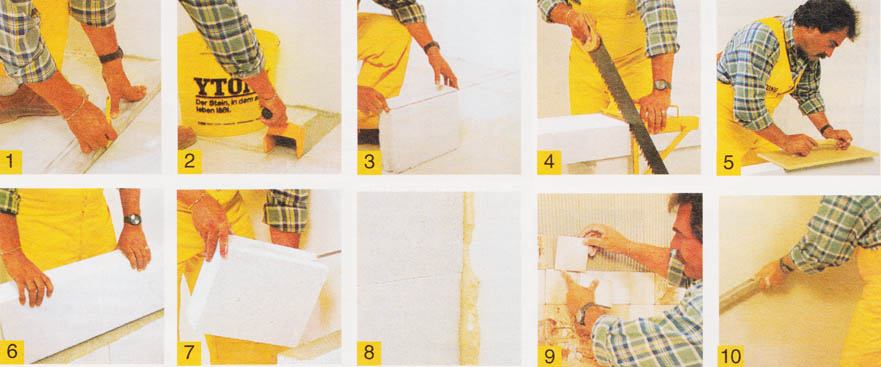

Jak układać kształtkę betonową? Prywatny dojazd do garażu jest zaklasyfikowany jako powierzchnia komunikacyjna o niewielkim obciążeniu, dlatego nie jest tutaj potrzebna jakaś specjalna podbudowa. Bez względu na to, czy mamy do czynienia z kostką brukową zwykłą czy betonową, sposób postępowania jest zawsze taki sam: najpierw usuwa się wierzchnią, luźną warstwę ziemi aż do twardego podłoża. Musi ono znajdować się co najmniej 30-35 cm poniżej późniejszej warstwy bruku. Podłoże należy dodatkowo ubić wibratorem.

Jak układać kształtkę betonową? Prywatny dojazd do garażu jest zaklasyfikowany jako powierzchnia komunikacyjna o niewielkim obciążeniu, dlatego nie jest tutaj potrzebna jakaś specjalna podbudowa. Bez względu na to, czy mamy do czynienia z kostką brukową zwykłą czy betonową, sposób postępowania jest zawsze taki sam: najpierw usuwa się wierzchnią, luźną warstwę ziemi aż do twardego podłoża. Musi ono znajdować się co najmniej 30-35 cm poniżej późniejszej warstwy bruku. Podłoże należy dodatkowo ubić wibratorem.

Teraz nanosi się tzw. warstwę nośną, względnie filtracyjną o grubości co najmniej 25 cm. Najodpowiedniejszy jest materiał mrozoodporny, ziarnisty, jak np. żwir lub tłuczeń. Po ubiciu i wyrównaniu tej warstwy, rozprowadza się podsypkę piaskową. Rodzaj podsypki uzależniony jest od złóż występujących w okolicy: może to być piasek lub miał kamienny (wielkość ziaren 0/5 mm). Grubość podsypki powinna wynosić w luźnym stanie (przed ubiciem) 4-5 cm. Na razie nie ubija się tej warstwy, zostanie ona później utwardzona razem z wyłożoną kostką brukową. Ponieważ ostateczną wysokość powierzchni bruku osiąga się dopiero po ubiciu wibratorem, należy ułożyć ją ok. 1 cm do 2 cm wyżej (w zależności od materiału podsypki). Ważne jest, aby cała powierzchnia podsypki była równo rozprowadzona. Przy układaniu nie można po niej stąpać – należy zawsze pracować od strony brukowanej powierzchni.

W celu uniknięcia zbędnego przycinania betonowych kształtek, pierwszy rząd układany jest pod kątem prostym do powierzchni krawężników. Należy pamiętać o zachowaniu minimalnej szczeliny. Spoiny wypełnia się później suchym piaskiem.

Ułożoną kostkę (koniecznie suchą) ubija się wibratorem z nałożonym ochraniaczem ślizgowym, który chroni powierzchnię betonowych kształtek. Jeżeli nie stosuje się krawężników, należy zabetonować boki ubijanej powierzchni lub zabezpieczyć je kantówką, która zapobiegnie usuwaniu się brzegów. Po ubiciu całej powierzchni należy jeszcze raz posypać ją piaskiem, tak aby wypełnić szczeliny do samej góry.

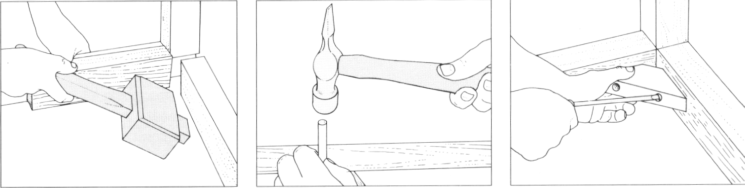

Kostkę brukową z naturalnego kamienia osadza się w podłożu przy pomocy młotka z osłoną gumową na głębokość 3-5 cm. Następnie wypełnia się szczeliny i ubija wibratorem, wyposażonym w płytę – bez osłony ślizgowej. Kamienie muszą być osadzone w podsypce na głębokości równej 2/3 ich wysokości. Do wypełnienia spoin używa się miału kamiennego połączonego z masą bitumiczną lub zaprawę spoinową na bazie cementowo-wapiennej.